CEO Message: How RunpWell Ensures Wallpaper Color Consistency

- Julie Li

- Aug 4, 2025

- 3 min read

Updated: Oct 26, 2025

By Jule Li, CEO of RunpWell Decor

Across the global wallpaper market—from boutique retailers in the US to commercial contractors in the UAE—one issue silently undermines customer trust, brand reputation, and project timelines: color inconsistency.

It often begins with a simple reorder. You place an order expecting the same “Stone Grey” as last time—but what arrives looks like “Ash Blue.” Your client notices. They complain. Suddenly, you’re dealing with returns, apologies, and delays.

The root cause is not the design. Not the print quality. It’s the lack of control over inventory and warehousing.

This is the hidden weak point in most wallpaper supply chains—and at RunpWell Decor, we solved it head-on.

How Warehouse Control Improves Wallpaper Color Consistency

Achieving true wallpaper color consistency requires more than perfect printing—it demands precise warehouse control. Even if every roll meets quality standards at the production line, poor inventory rotation or unsynchronized batch management across multiple warehouses can still cause visible differences. By aligning batch turnover, standardizing storage conditions, and integrating real-time tracking systems, brands can ensure every shipment matches exactly what customers expect.

The True Cost of Wallpaper Color Inconsistency

Wallpaper buyers—whether B2B distributors or interior designers—expect consistent results. When colors shift between batches, the damage goes beyond aesthetics.

Here’s what color inconsistency often leads to:

Problem | Real-World Impact |

Reorders don’t match original batch | Customer dissatisfaction, returns, refunds |

Designers lose confidence | Loss of recurring projects or referrals |

Project delays | Missed construction deadlines, penalties |

Poor online reviews | Lower ratings, less visibility on e-commerce |

Extra costs | Reprints, express shipping, rescheduling labor |

These aren’t minor issues—they’re strategic risks.

Why Most Wallpaper Factories Can’t Solve It

The main reason? They don’t own their warehouses.

Many wallpaper manufacturers rely on external 3PL (third-party logistics) warehouses. These warehouses are not optimized for color control. They mix batches, store in unstable temperatures, and have no digital tracking across production and stock.

Once your product leaves the factory, it's out of their hands—and that’s where things fall apart.

RunpWell’s Advantage: Warehouse Control at Every Step

At RunpWell, we manage everything from printing to packaging to warehousing and delivery. Our approach is built to eliminate color variance before it ever reaches you.

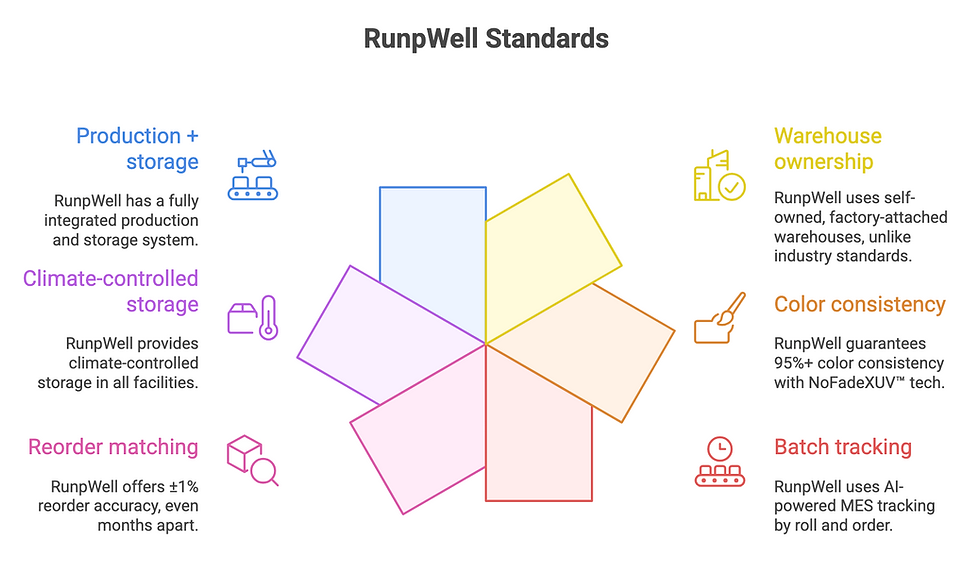

What Makes RunpWell Different:

Capability | Industry Standard | RunpWell Standard |

Warehouse ownership | Outsourced, multi-client storage | Self-owned, factory-attached warehouses |

Color consistency guarantee | None | 95%+ with NoFadeXUV™ color control tech |

Batch tracking | Manual or disconnected | AI-powered MES tracking by roll and order |

Reorder matching | Risk of mismatch | ±1% accuracy for all reorders, even months apart |

Climate-controlled storage | Rare | Standard in all facilities |

Production + storage link | Disconnected | Fully integrated system |

We currently operate four self-owned manufacturing bases in China and manage over 15 vertically integrated supply chains, giving us unmatched flexibility and control in the wallpaper and surface décor industry.

What Global Buyers Gain from Our System

Our warehousing model isn’t just a backend operation—it creates measurable value for our clients worldwide.

For Retailers & Distributors:

Lower return rates

Higher customer satisfaction

Better product reviews

More predictable inventory planning

For Designers & Contractors:

No risk of batch mismatches

Confidence in reorders

Faster turnaround for urgent jobs

No need to “re-explain” color to clients

For Global E-Commerce:

Fewer disputes

Higher store ratings

Stable product listings without variation issues

Supporting Global Markets with Local Speed

To bring these advantages closer to our partners, we’re expanding globally with regional warehouses and fulfillment strategies:

North America: Fast-track OEM/ODM support for Amazon, Wayfair, and Walmart partners

Europe: Color-certified production for design-driven markets like Germany and Scandinavia

Middle East & Southeast Asia: Warehouse hubs serving hospitality megaprojects

Australia & South America: Climate-specific storage to meet local environmental challenges

No matter your region or use case—commercial, residential, DIY—we ensure that what your customer sees is always what they get.

Final Thought from the CEO

If your wallpaper supplier can't control where your product is stored, they can’t protect the color. They may give excuses like screen differences, lighting conditions, or dye lot variations—but these are just symptoms.

The real solution lies in full vertical control—from printing to warehousing.

At RunpWell Decor, we don't guess. We guarantee.

Let RunpWell be the factory behind your brand’s consistency. Contact us today to request samples, plan your next batch, or book a consultation.

—Jule LiCEO | RunpWell Decor

📞 +86 15738309271

Comments